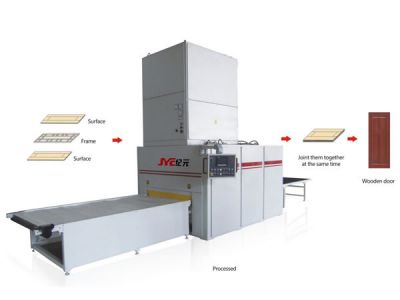

Radio Frequency Press

The veneering machine is great for laminating composite door and solid wood. This short cycle veneer press utilizes our brand new, patented technology. This new technology utilizes a radio frequency heating which only heats the glue line without penetrating the core veneer or wood frame, which ensures a high heating efficiency.

Technical Parameters of the Veneering Machine

| Model | GJT-PII-64A-JY | GJT-PI-100A-JY | |

| Power supply | AC, 380V, 50Hz, 3 phases(5 wires or customized) | ||

| Max working size | 2200x1000(mm) | 3050x1250(mm) | |

| Frequency | 6.78MHz | ||

| Cooling | Forced air cooled | ||

| Feeding | Auto feeding | ||

| Total pressure | 60T | 100T | |

| Control Type | PLC auto control, HMI screen | ||

| Protection mode | Over current protection, air pressure protection, door switch protection, vacuum tube over temperature protection. | ||

Features of the Veneering Machine

- Uniform heating

The compact high frequency glue press has a short cycle time and employs efficient high frequency technologies to ensure a uniform heating process, as well as enabling internal and external parts of the glue line to become the same temperature. This enhances the glue curing strength and improves overall product quality. - Short cycle and high efficiency

Due to the high radio frequency, the veneering machine comes with extremely fast heating times and a high heating efficiency. The heating time last only about 3 to 5 minutes. - Easily controlled heating process

The heating process of this veneering machine is easily controlled. When the power is on, heating starts. Turn the power off, and the heating process stops. Heating times can also be adjusted to obtain better control.

As a leading manufacturer and distributor of woodworking machinery in China, our veneering machine is exactly what you are looking for.

Applications

Get in Touch

Other Products