Radio Frequency Press High Precision Frame Assembly Machine

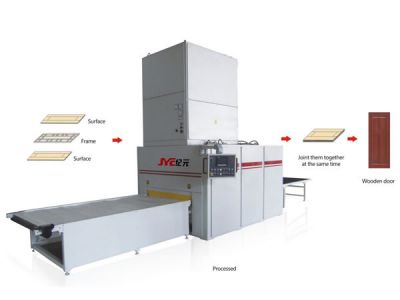

When it comes to looking for the right woodworking machine to assemble multiple varieties of wood frames, there are a lot of options, making the process confusing and stressful. Here at Jiyuan, we can alleviate that stress by providing you the best solution for wooden frame assembly with our radio frequency press. Our wood frame assembly machine applies a radio frequency heating technology, allowing for a faster batch production.

Our wood frame press machine employs a ball screw positioning device and a PLC automatic control system, allowing operators to set the assembly dimensions. It is an ideal radio frequency press for producing picture frames, cabinet doors, wooden doors, drawers, windows, other jointed wood frames with 45°, 90° or 135° angles, and MDF board frames. Whether wooden wedges are needed or not depends on the product sizes and technology of customer. However, nails are not necessary.

Technical Parameters of the Radio Frequency Press

| Model | GJJ-SI-3-JY | GJJ-SII-3-JY |

| Power supply | AC 380V, 50Hz, 3 phase four wire (or customized) | |

| Max. working size | 1800x800mm | 2800x800mm |

| Min. working size | 180x180mm | 180x180mm |

| Curing time | 5-20s | 5-20s |

| Overall size | 2800x1110x1612mm (L*W*H) | 3820x1470x1722mm(L*W* H) |

| Weight | 0.8T | 1T |

| Motor type | Servo motor | |

| Mechanical drive | Precision ball screw | |

| Output power | 3kW | |

| Control type | PLC control and touch screen interface | |

| Adjustment type | Automatically adjustment | |

Characteristics of the Radio Frequency Press

- Radio frequency heating

This wood frame assembly machine adopts a high frequency dielectric heating technology that heats only the glue line, making the wait time short and saving energy. One frame can be assembled in anywhere from 5 to 20 seconds. - PLC control system

This radio frequency press uses a PLC automatic control system, which is specifically designed with a user friendly touch screen interface that displays information needed such as frame dimensions, heating time, pressure maintenance time and more. After dimensions are set, the woodworking equipment will automatically readjust to the correct heating and pressure maintenance levels to complete one production cycle. - Self-checking fault function

This frame assembly machine comes equipped with a self-checking fault system. When an error occurs, the system will sound an alarm and perform a search for the location of the error. - High precision

This radio frequency press has a ball screw and linear guide to help ensure a precise fit. This wood processing equipment also utilizes a state-of-the-art servo motor. The motor combines the ball screw and linear guide to ensure the diagonal line error is smaller than half a millimeter, making this equipment superior to a stepping motor in terms of precision and speed. - Excellent Safety Device

Our radio frequency press is outfitted with excellent shielding and protective devices to guarantee operator and equipment safety.

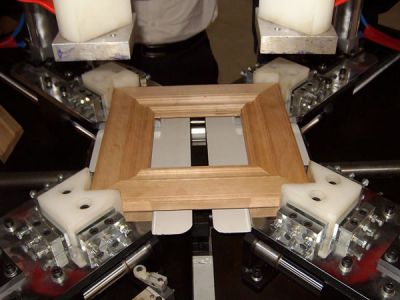

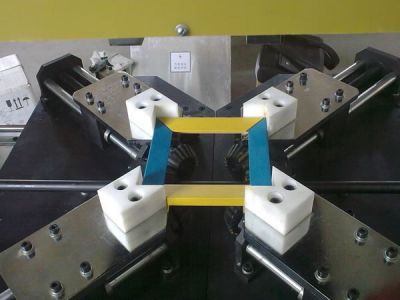

Parts Figure