Vacuum Kiln, 25 Cube Vacuum Dryer Machine For Large Section Timber Drying

Jiyuan manufactures vacuum kilns for drying large sections of lumber and square edge timber and has become a respected lumber dryer and timber dryer manufacturer in China. As compared with conventional wood drying equipment, our radio frequency vacuum kilns, or simply RFV kilns, can avoid and solve the problem of moisture content differences.

Technical Parameters of Vacuum Kiln

| Capacity | 3CBM | 4CBM | 6CBM | 10CBM | 14CBM | 20CBM | 30CBM |

| Model | GJG-3II-10B-JY | GJG-4II-20B-JY | GJG-6II-30B-JY | GJG-10II-30B-JY | GJG-14II-50B-JY | GJG-20II-80B-JY | GJG-30II-80B-JY |

| Power | AC, 380V, 50Hz, 3 phases(5 wires or customized) | ||||||

| Output Power | 10KW-120KW | ||||||

| 27 years of experience in HF technology. This machine can save power and improve efficiency | |||||||

| Wood Loading Size | L3000mm x W1000 x H1000 (3CBM capacity) | ||||||

| L4000mm x W1000 x H1000 (4CBM capacity) | |||||||

| L6000mm x W1000 x H1000 (6CBM capacity) | |||||||

| L6000mm x W1300 x H1300 (10CBM capacity) | |||||||

| L8000mm x W1300 x H1300 (14CBM capacity) | |||||||

| L8000mm x W1600 x H1600 (20CBM capacity) | |||||||

| L8000mm x W2000 x H2000 (30CBM capacity) | |||||||

| Other capacities can also be customized. | |||||||

| Functions | Can dry all kinds of wood, especially for rosewood and hardwood. | ||||||

| High Frequency | 6.78MHz | ||||||

| Max Pressure | -0.092MPa | ||||||

Radio Frequency Vacuum Kilns vs Conventional Wood Dryers

Wood that is over 10 cm thick generally falls into the large section category. It is difficult to completely dry this type of wood using conventional drying methods like steam drying and hot plate drying because both of these methods adopt a heat conduction method to heat the wood. This results in temperature differences between the wood surface and core, leading to a significant difference in the moisture content, such as a surface moisture content of 10% and a core content of more than 20%. The thicker the wood gets, the more obvious this difference becomes. Wood also cracks and deforms easily using these methods, which leads to deformed products made from this wood.

Our radio frequency vacuum kiln employs the use of high frequency dielectric heating methods, which achieve selective heating. Wood cores with high moisture content will be exposed to higher heating temperatures, and wood with lower moisture content will be dried using lower temperatures. By doing so, wood heating becomes more uniform and balances the moisture content, ensuring an excellent drying effect. This wood drying machine also considerably reduces wasted wood and lowers factory costs.

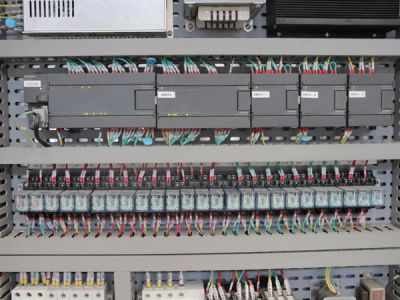

Parts Figure

Application